Micro LED Process Technology

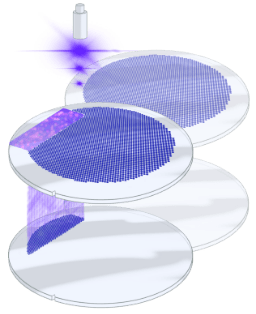

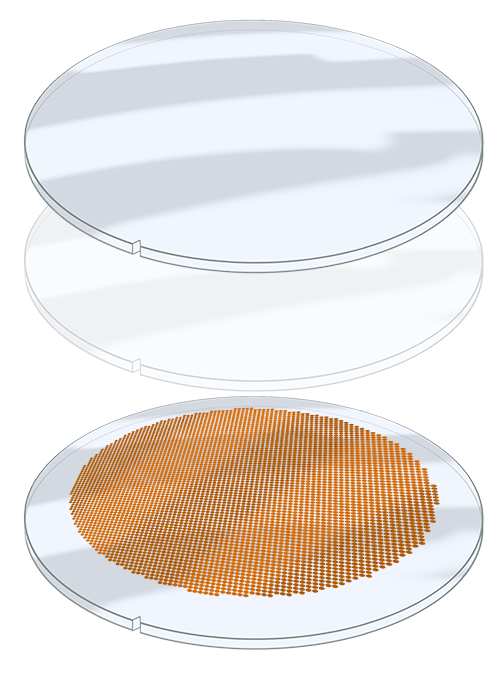

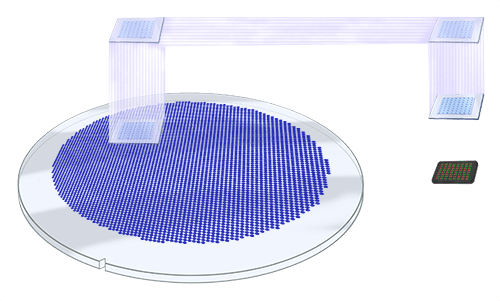

Micro LED Wafer (before LLO)

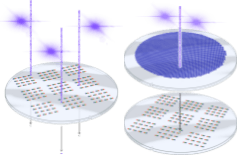

Micro LED display is regarded as the most promising candidate for next-generation display, however high manufacturing cost is major hurdle for the mass production due to difficulty to handle extremely small LED chips.

Improvement of complexity and low yield of Micro LED chip manufacturing and transferring process is the key for mass production, and we have utilized and developed our technology to solve these problems.

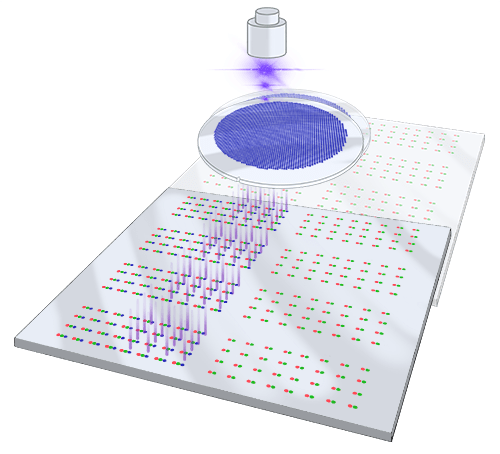

Process Solution for Micro LED

Low Cost Production

Shin-Etsu Unique Material Technology

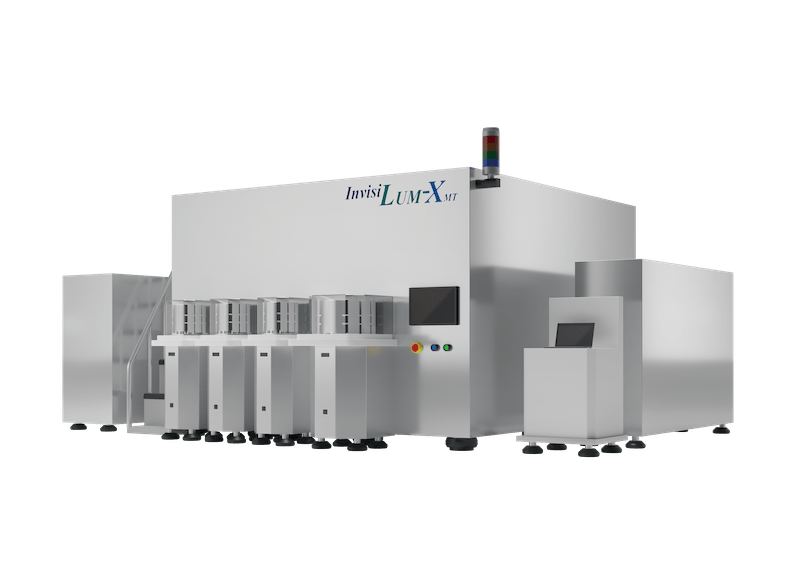

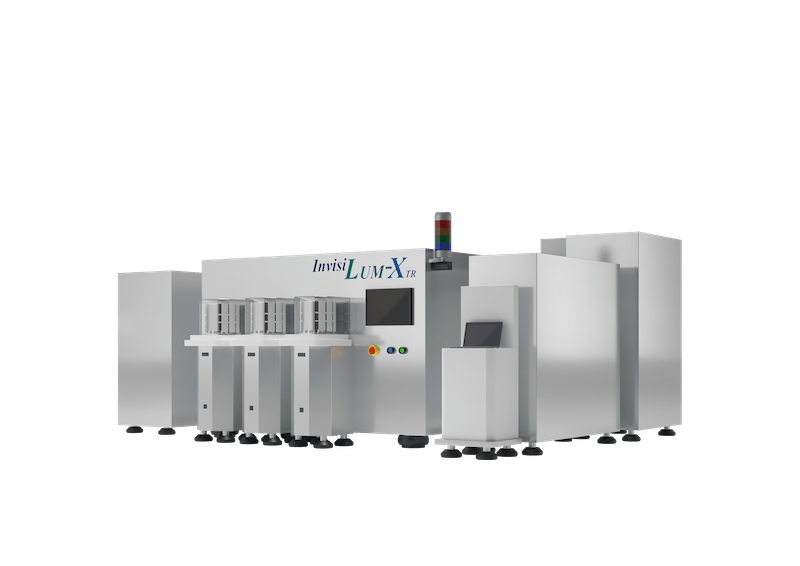

Excimer Laser Equipment